How Is A Cpu Designed – A Step-by-Step Guide to Processor Engineering!

Discover how a CPU is designed, from architecture to manufacturing and testing. This guide simplifies the complex process behind modern processor development.

This article explores CPU design, from planning to manufacturing and testing. We cover key stages like architecture, logic design, fabrication, and quality control. Whether you’re a tech enthusiast or a beginner, this guide simplifies CPU engineering.

Concept and Architectural Planning:

The design of a CPU begins with the conceptual phase, where engineers define the objectives and requirements for the processor. During this stage, key questions are addressed:

- What type of CPU is being designed? (General-purpose, embedded, or specialized?)

- What performance goals should be met? (Clock speed, power efficiency, core count, etc.)

- What manufacturing constraints exist? (Fabrication technology, cost, and power consumption.)

At this point, computer architects outline the instruction set architecture (ISA), which defines how software interacts with the processor. Popular ISAs include x86, ARM, and RISC-V. The CPU’s core architecture is determined based on performance needs, balancing factors such as processing power, energy efficiency, and parallelism.

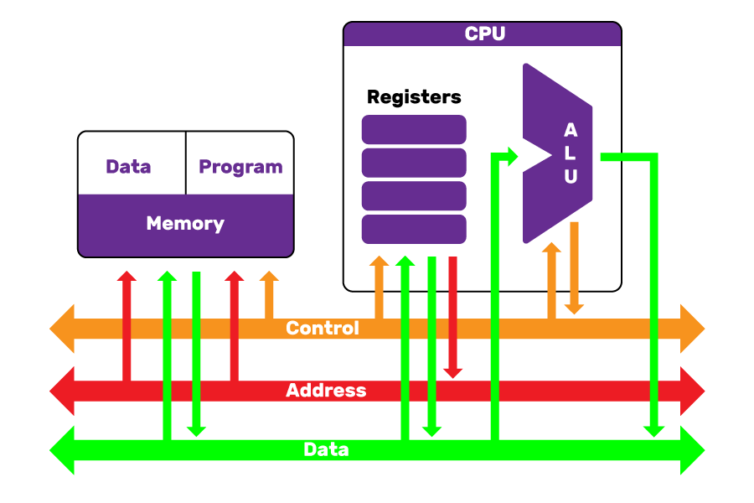

Microarchitecture and Logic Design:

Once the high-level architecture is finalized, the next step is defining the microarchitecture. This stage determines how different components of the CPU, such as the arithmetic logic unit (ALU), registers, cache memory, and control logic, interact.

The CPU is broken down into individual functional units:

- Fetch Unit: Retrieves instructions from memory.

- Decode Unit: Translates instructions into control signals.

- Execution Unit: Performs computations and logic operations.

- Memory Unit: Handles data storage and retrieval.

- Control Unit: Manages coordination between different CPU components.

This stage also involves designing the pipeline structure, which allows multiple instructions to be processed simultaneously to improve efficiency. The complexity of pipelining depends on the CPU’s intended performance. Advanced CPUs include features like speculative execution, branch prediction, and out-of-order execution to further enhance performance.

Read More: Blueiris Using Cpu – A Complete Guide!

Verification and Simulation:

Before moving to physical design, engineers must ensure that the logic design functions correctly. This is done through simulation and verification:

- Logic Simulation: Testing the design using software models to ensure correctness.

- Functional Verification: Ensuring the CPU adheres to its ISA and performs correctly under various conditions.

- Power and Performance Analysis: Measuring power consumption and performance efficiency.

- Fault Tolerance Testing: Evaluating how the CPU handles unexpected failures and errors.

Simulation tools and emulators help detect design flaws early, reducing the risk of costly errors later in the manufacturing process. Additionally, performance benchmarks are conducted to ensure the CPU meets industry standards and intended performance targets.

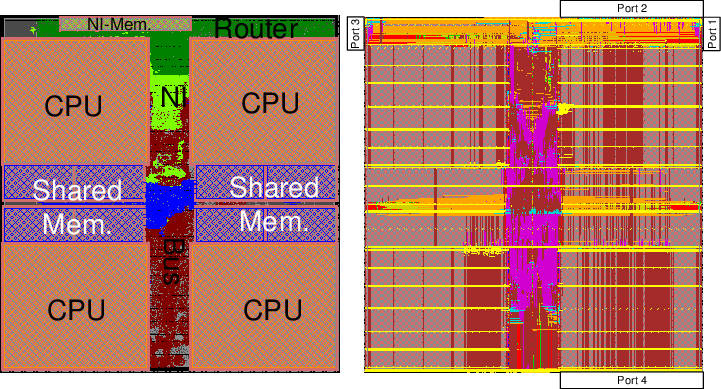

Physical Design and Layout:

Once the logic is verified, the next step is translating the design into a physical layout that can be manufactured. This involves:

- Transistor-Level Design: Mapping logic gates to physical transistors.

- Floor Planning: Organizing the placement of different components within the silicon die.

- Routing: Connecting transistors with metal interconnects to form electrical pathways.

- Clock Distribution and Power Planning: Ensuring stable clock signals and efficient power distribution across the CPU.

- Thermal Management: Designing heat dissipation mechanisms to prevent overheating.

This stage is highly complex and relies on electronic design automation (EDA) tools to optimize layouts for performance and efficiency. Advanced CPUs utilize techniques such as FinFET and EUV lithography to achieve higher transistor density and efficiency.

Fabrication and Manufacturing:

Once the physical design is complete, the CPU moves to the fabrication phase. Modern CPUs are manufactured using semiconductor fabrication processes, often at nanometer scales (e.g., 3nm, 5nm, 7nm, etc.).

The fabrication process involves several steps:

- Photolithography: Using light to etch the CPU design onto a silicon wafer.

- Doping and Etching: Modifying semiconductor properties to create transistors and circuits.

- Deposition: Adding layers of material to build interconnects and insulation.

- Chemical-Mechanical Planarization: Flattening surfaces for better layering.

- Testing and Yield Analysis: Ensuring that only functional chips proceed to packaging.

- Packaging: Placing the CPU into protective housing with necessary electrical connections.

After fabrication, the CPUs are tested extensively for defects. Chips that meet performance standards are packaged and prepared for distribution. CPUs that fail initial tests may be salvaged through binning or repurposed into lower-end models.

Testing and Quality Control:

Before CPUs are shipped, they undergo rigorous testing to ensure they meet specifications. This includes:

- Burn-In Testing: Running the CPU under extreme conditions to identify early failures.

- Functional Testing: Verifying that all cores and cache function correctly.

- Performance Binning: Categorizing CPUs based on their performance characteristics (e.g., clock speed, power efficiency).

- Security and Reliability Checks: Ensuring the CPU is resistant to vulnerabilities like Spectre and Meltdown.

Some CPUs that fail to meet high-performance standards are repurposed as lower-tier models to minimize waste. Additionally, firmware and microcode updates may be issued post-production to enhance security and performance.

Read More: Cpu Vdd Voltages – Safe Limits & Optimization!

Final Integration and Market Release:

Once testing is complete, CPUs are integrated into products such as laptops, desktops, and servers. Software optimizations, firmware updates, and driver development help ensure compatibility with existing ecosystems. CPUs also undergo validation with various motherboards, RAM modules, and GPU configurations to ensure stability.

Major CPU manufacturers like Intel, AMD, and ARM spend years refining designs before releasing new generations of processors. Once CPUs reach the market, they undergo continued updates and optimizations through software patches and microcode updates. Furthermore, the competition in the industry drives innovation, leading to faster, more efficient, and more powerful CPUs with each new generation.

Future Trends in CPU Design:

As technology advances, CPU design continues to evolve to meet increasing demands for performance and efficiency. Some of the key trends shaping the future of CPUs include:

- Chiplet Architectures: Instead of a monolithic die, manufacturers are using smaller chiplets interconnected for better scalability.

- AI and Machine Learning Acceleration: CPUs are incorporating specialized AI cores to handle machine learning workloads more efficiently.

- Quantum Computing Integration: Research is ongoing into integrating quantum processors with traditional CPUs for hybrid computing.

- Energy Efficiency Innovations: Reducing power consumption while maintaining performance is a primary focus for modern CPU designs.

FAQ’s

1. What is the first step in designing a CPU?

The first step in CPU design is conceptual and architectural planning, where engineers define performance goals, instruction set architecture (ISA), and core specifications to meet intended use cases.

2. How do engineers verify that a CPU design works correctly?

Engineers use logic simulation, functional verification, and power analysis to test the CPU in virtual environments before fabrication, ensuring it meets efficiency and performance requirements.

3. What role does lithography play in CPU manufacturing?

Lithography is a critical fabrication step that etches intricate transistor patterns onto silicon wafers using ultraviolet light, enabling the creation of modern nanometer-scale CPUs.

4. Why do some CPUs perform better than others even within the same model?

CPUs are binned based on their performance during post-manufacturing tests, where factors like silicon purity and power efficiency determine their final clock speeds and capabilities.

5. How is CPU design evolving for the future?

Future CPUs are integrating chiplet architectures, AI accelerators, and energy-efficient designs to improve scalability, machine learning performance, and power consumption.

Conclusion:

Designing a CPU is an incredibly complex process that involves multiple disciplines, including computer architecture, electrical engineering, and semiconductor physics. From conceptualization and microarchitecture to fabrication and testing, every step requires meticulous planning and precision. As technology advances, CPUs continue to become more powerful, energy-efficient, and specialized, driving innovation across the computing industry.